Current plant-based analogs rely on deconstructed plant tissues that are modified and combined with other ingredients in an attempt to create dairy and meat-mimicking structures and sensory profiles. In his presentation, “Strategic Use of Food Structure of Plant-based Formulations & Cleaner Labels,” at the 2023 Clean Label Conference, Jeff Casper, MSc, Partner, Voyageur Foodworks, compares current vs. alternative paths to achieve specific structures. Insights are provided into the development of structure-based formulation strategies that can lead to better formulation decisions and outcomes.

The challenge in most plant-based analog formulations is that the ingredients available to formulators are isolated from plant structures and purified in non-standardized processes. Each plant-based protein is unique, based on its source and processing, which results in highly variable and modified functionalities within an ingredient class, said Casper,

Formulators seek to create new structures using these ingredients in a unique way to mimic animal-based protein. “Structure determines the textural perception, flavor release, nutrient bioavailability, and environmental impact of plant-based foods,” Casper added.

Protein Extraction Methods

Casper noted that when we extract protein from seeds, we might use aqueous, salt or dry fractionation methods to physically separate protein bodies from starch granules. For example, the pH is often varied for both the extraction and isoelectric precipitation steps in aqueous pea protein extraction. This dramatic pH swing impacts the functionality of protein ingredients.

Dry fraction methods use air classification based on density to separate proteins from starch granules. This process has limits on purity, with the maximum approaching about 70% protein using currently available technology. The dry-fractionation process also leaves more grassy or beany notes from the native material.

Not all proteins produced by the same methods give the same result, so it is essential to evaluate the impact of the process on the functional properties of protein ingredients. Breeding is another method to modify proteins. In the future, Casper said, we will see much more work around genetics in protein processing.

A good strategy provides a clear roadmap of guiding principles or rules when creating new protein structures. This defines the properties that ingredients in the formula should have to achieve desired goals.

Strategies for New Structures

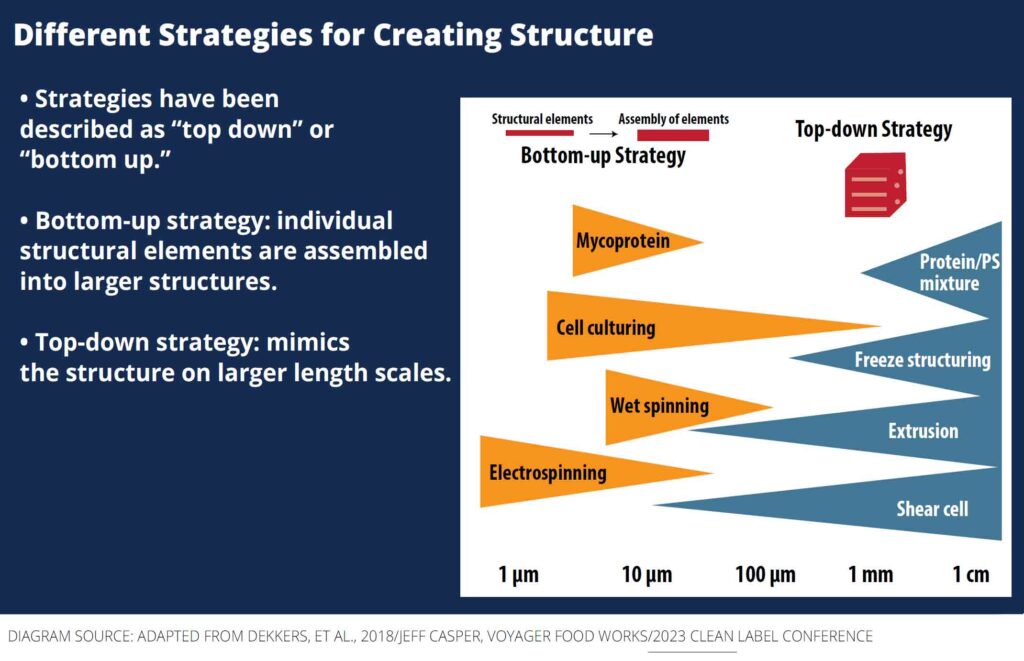

Food companies can use a top-down or bottom-up strategy. A bottom-up approach assembles a structure to resemble muscle tissues, for example. In contrast, a top-down strategy takes existing material and manipulates or deforms it into the desired structure. (See diagram “Different Strategies for Creating Structure.”)

One case study offered by Casper illustrates the replacement of methylcellulose in plant-based hot dogs and sausages using emulsified, filled protein gels. The sausages also incorporate particulates of a high-moisture, extruded material made from pea or soy protein, plus gluten. The goal is to create a protein gel that is as firm, elastic, and springy as methylcellulose.

Casper used transglutaminase to set the gel. As it approaches the isoelectric point, the gel’s pH affects firmness, elasticity, and syneresis. Oil droplets were dispersed into the gels as an active or inactive filler. Different pea proteins have differing resiliency and springiness, depending on their processing. In this case study, each formulation he worked with was 16% protein, 10% oil and water. This material can then be stuffed into a casing and cooked in a smokehouse.

Casper’s second case study illustrates fixing hydrocolloid filaments in pea protein gels to create a plant-based scallop using a water-in-water emulsion. This application uses two biopolymer solutions that are relatively thermodynamically incompatible. Phase 1 is a 10% pea protein solution, and phase 2 is a 0.6% pectin solution.

These two phases want to repel each other. Shear cell technology creates filaments, which are then set with transglutaminase. The product can be pan-seared and is visually and texturally similar to a real scallop.

The third example discussed was a plant-based yogurt. Plant-based yogurts have flavor and color issues; fermentation can act differently on those proteins. The goal is to obtain the cleanest-tasting protein that forms the best emulsion. Soy protein yogurts have been around for a long time. Replacing these with pea or other plant proteins is challenging, noted Casper.

A fluid gel approach uses a system of gel particles dispersed in a non-gel continuous phase. This will work with almond, pea milk, oilseed proteins, or soy protein. Casper’s first approach used agar and gellan fluid gel to create a yogurt with 11g of protein per 150-gram serving. His second approach used a pectin source, such as citrus fiber, for a cleaner label.

In conclusion, Casper pointed out that we don’t always have to mimic animal protein. By developing imaginative applications, we can create unique foods with high consumer appeal.

“Strategic Use of Food Structure of Plant-based Formulations & Cleaner Labels,” Jeff Casper, MSc, Partner, Voyager Food Works.

Click on the phrases below to see related articles on these topics at FoodTrendsNTech.com.