“Protein quality is generally assessed as a function of its ability to meet the biological needs of the consumer,” explained Matthew Nosworthy, Ph.D., Food Science and Nutrition Research Scientist with Guelph Research and Development Centre, Agriculture and Agri-food Canada. His topic, “Enabling Protein Claims & Improved Protein Quality by Blending & Processing Protein Ingredients,” was presented at the 2022 Protein Trends & Technologies Seminar.

Aspects of protein quality include sustainability, functionality, color, taste, health profile, cost and—the focus of this talk—nutritional quality. “The nutritional quality of a protein is important for consumers to assess how ‘good’ it is for them,” noted Nosworthy. “For commercial manufacturers, it is important for ingredient selection and package labeling.”

Assessing Protein Quality

“Methods for protein quality in Canada and the U.S. are determined by the protein efficiency ratio (PER) and protein digestibility corrected amino acid score (PDCAAS), respectively,” explained Nosworthy. Released in 2013 by the Food and Agricultural Organization in conjunction with the World Health Organization, the digestible indispensable amino acid score (DIAAS) is a novel approach to measuring protein quality. Still, it is not currently used as a regulatory method. PDCAAS assesses nitrogen digestibility rather than amino acid digestibility used in DIAAS.

The PDCAAS is determined from the product of the AAS (calculated by dividing the food AA by the AA in the reference pattern, taking into account the lowest AA) and True Fecal Protein Digestibility (TFPD, determined by fecal nitrogen output divided by the dietary nitrogen input), with a correction for endogenous losses. Values are truncated at 1.00, so proteins of higher quality are not identified, and the quality of any blend may be inaccurate if truncation is required.

Nosworthy explained that “there are ways that PDCAAS data can be misrepresented. Variables include how the amino acid composition was determined and which reference pattern was used for the calculation of the AAS.” For the latter, the year of publication and the age range used can impact the PDCAAS. For protein digestibility, modeling with an animal or human study or in vitro (i.e., bench-top assessments) testing can yield different results.

Improving protein quality by blending is important in dietary planning and interventions and for ingredient selection related to quality for package labeling. Nosworthy described research that found a correlation between both digestibility and PDCAAS values generated from in vitro and in vivo methods. (Nosworthy, MG, House JD. Cereal Chem. 2017/ https://onlinelibrary.wiley.com/doi/abs/10.1094/CCHEM-04-16-0104-FI). There is an increasing desire to reduce animal experimentation to determine protein quality.

The blending of 50:50 of extruded buckwheat with pinto resulted in higher protein efficiency ratio values, increased digestibility, and greater PDCAAS (Nosworthy et al. J. Agric. Food Chem. 2017/ https://pubs.acs.org/doi/10.1021/acs.jafc.7b00697).

Another study showed that the PDCAAS for processed beans was higher than the DIAAS (61 vs. 45%). Extrusion and/or cooking of various beans resulted in higher PDCAAS (66% average) and DIAAS values (61% average) than baked (52 and 48%). A significant correlation was found between PDCAAS and in vitro PDCAAS (R2 = 0.7497). (Nosworthy, MG et al. Nutrients. 2018/ https://www.mdpi.com/2072-6643/10/6/671)

Pulse Inclusion

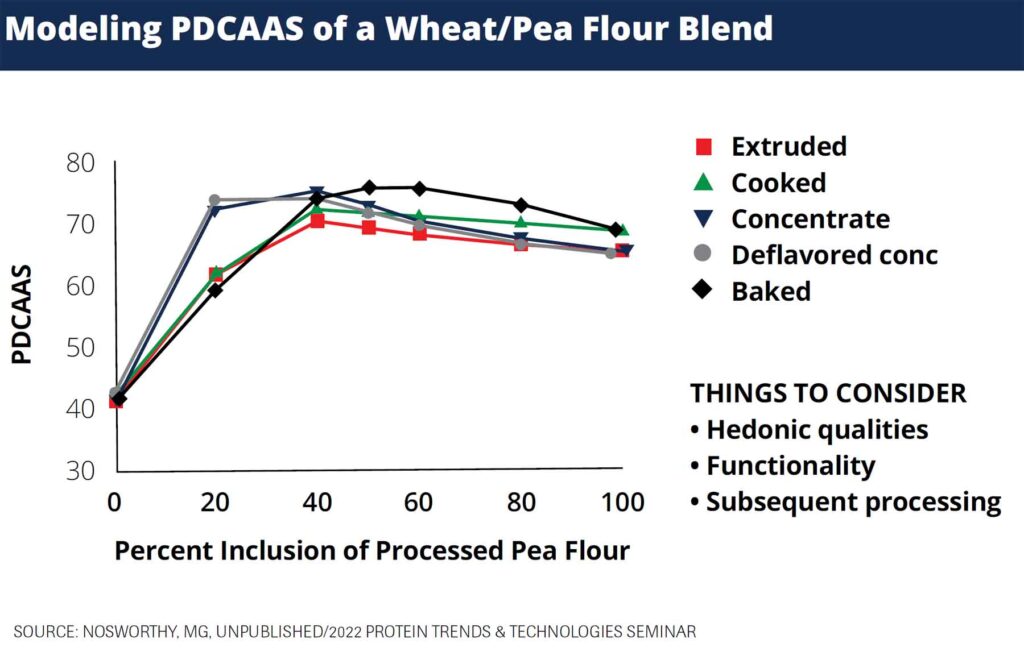

The blending of wheat flour with increasing pulse inclusion will increase PDCAAS values from 0.39 to upwards of 0.80, supporting how blends can be designed to maximize quality. (See chart “Modelling PDCAAS of a Wheat/Pea Flour Blend.”)

Nosworthy also presented processing data using pulses that showed dramatic effects on PDCAAS values following cooking, baking and extrusion; enzymatic hydrolysis using different proteases; and fermentation with various microorganisms, times of exposure, and solid-state vs. liquid conditions.

Protein content claims for foods are based on the product of the PDCAAS and the protein content of the representative amount customarily consumed (RACC)—which means the serving size can affect the protein claim. For example, sunflower seeds with a PDCAAS of 0.66 but a RACC value of only 30 result in a Corrected Protein Content in RACC (g) of 4.1, and no claim is permitted. In contrast, whole green lentils with a PDCAAS of 0.63 and a RACC of 35 have a Corrected Protein Content in RACC of 5.8. In this case, a “Good Source of Protein” claim is permitted.

PDCAAS of greater than 0.20 is considered a “significant source of protein” for all non-infant foods; for DIAAS, the cut-off is greater than 75. Nosworthy stated that “a value of 5 to 9.9g is a ‘good source’ of protein; 10g or greater is an ‘excellent source.’”

The limitations of plant proteins include allergenicity (including those from peas) and secure supply chains (e.g., rice, pumpkinseed, microalgae). Compositional challenges include low protein content (cereals) and anti-nutritional factors that reduce digestibility, such as protease inhibitors, tannins, phenolics, and phytate. “Challenges also include limiting AA in cereals that include lysine, leucine in ancient grains, and methionine, cysteine, and tryptophan in pulses,” Nosworthy said.

“Protein quality claim assessment is complex, with different protein sources possessing their unique challenges,” summarized Nosworthy. “Blends can be designed theoretically to maximize quality; selecting an appropriate processing method is critical.”

“Enabling Protein Claims & Improved Protein Quality Blending By & Processing Protein Ingredients,” Matthew Nosworthy, Ph.D., Food Science and Nutrition Research Scientist with Guelph Research and Development Centre, Agriculture and Agri-food Canada

Click on the phrases below to see related articles on these topics at FoodTrendsNTech.com.