Different approaches to reducing or replacing sugar in formulations with nonnutritive sweeteners, naturally occurring sugars, fibers, and flavor enhancers can be taken. Blending culinary and food science techniques, Zal Taleyarkhan, Corporate Research Chef, and Jenn Farrell, Director of R&D, both at Charlie Baggs Culinary Innovations (CBCI) offered insights into this topic. Their 2023 Clean Label Conference presentation titled, “No Sugar Coating—A Practical Approach to Delivering Sweet Flavor Without Calories,” focused on formulation creation and ingredient identification as they dived into the importance of flavor building and formula modification from a culinary and gold-standard perspective.

“Flavor is an illusion, a sleight of hand to trick the senses,” declared Taleyarkhan. One challenge in working with sweet flavors is that many companies try to reduce sugar, but sugar-reduction solutions are constantly scrutinized. For example, the Cleveland Clinic recently suggested that erythritol increases the risk of cardiovascular conditions.

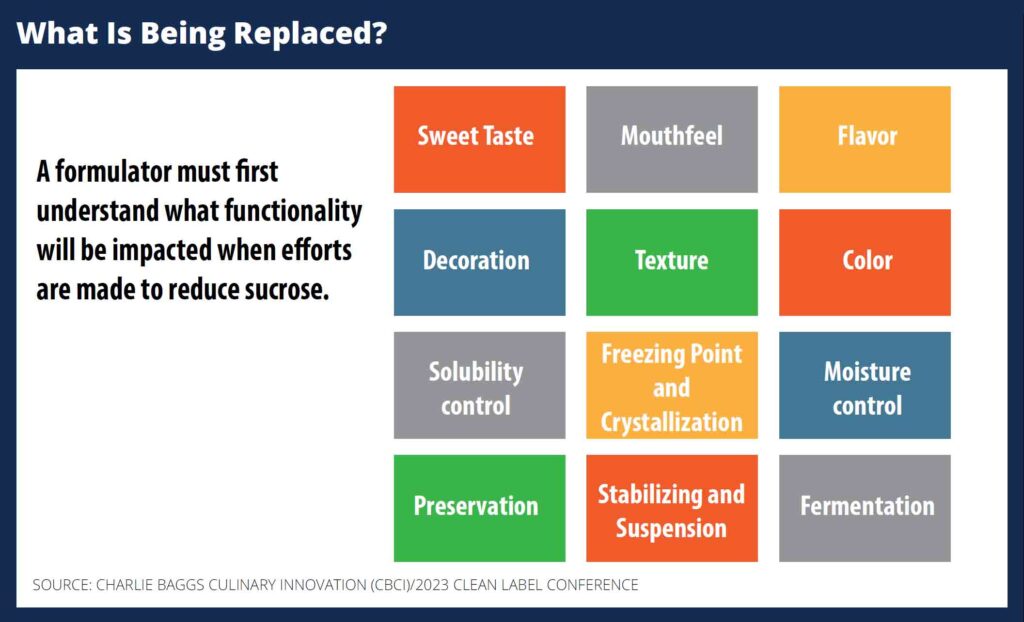

Additionally, “Sugar provides many properties to foods,” explained Taleyarkhan. See the chart “What is Being Replaced?” With its sweet taste, sugar can mask bitter flavors and enhance fruity and brown flavors. The particle size of sugar affects mouthfeel. Sugar can enhance flavor, including savory flavors, when used at low levels and more complex brown sugar flavor profiles. It can be used as a decoration on cakes. It helps produce various textures and can add body and viscosity, as in meringues.

In the presence of heat and protein, sugar will add color. Brown and golden sugars create unique shades. The sugar’s particle size can be used for solubility control based on the rate at which it dissolves. In frozen desserts, sugar depresses the freezing point. Smaller ice crystals create a smoother texture. Invert sugar inhibits recrystallization and thus aids moisture control in some applications.

In combination with an acid, sugar facilitates natural preservation in jams, preserves, and chutneys. By increasing viscosity, sugar can stabilize the dispersion of active ingredients in liquid medicines. Sugar also serves as a food source for yeast fermentation, noted Taleyarkhan.

When replacing sugar, one must consider bulk, body, mouthfeel, taste, and balance of flavor in the formula. There is no “one size fits all.” Using fibers, proteins, flavorful ingredients, flavor enhancers, naturally occurring glutamate, and non-nutritive carbs in unison is a way forward.

Some sugar is essential to bring the formula to life. Everything we do in product development to change flavor profiles is a deception—a way to confuse the senses and rebalance the interplay between sweet, sour, salty, and bitter perceptions, said Taleyarkhan. The flavors we want to be intensified should get onto your taste buds first.

Specific ingredients were offered as part of a practical approach to delivering sweet flavor.

Spices and flavor combinations. Not only do spices have anti-inflammatory properties, but they also work as fantastic flavor maskers. Modulating the amount of salt in savory applications is essential in sugar reduction. A dark cocoa mass or chocolate heightens mildly sweet items. Molé dressing is a great example. Cocoa pulp, a sustainable new ingredient, can partially replace refined sugar in chocolate and confections.

Fibers/gums/non-nutritive sweeteners. Some soluble corn fiber can reduce sugar content in chocolate while retaining similar sweetness levels and leaving no aftertaste. A blend of gum acacia and stevia can work as a sugar alternative. Some fibers have behavior comparable to a bulking agent, added Taleyarkhan.

Proteins/fats. Proteins, in combination with fat and soluble fibers, have a fantastic effect on a formula’s ability to reduce sugar. Sunflower protein enhances sweet, nutty, and roasted flavor profiles. Isolates and fiber protein blends can slow down the staling process.

Flavor enhancers. Familiar flavor enhancements, such as tomato concentrate, stevia extracts, yeast extracts, mushroom extracts,

fermented products and protein sources can enhance flavor and facilitate sugar reduction.

Naturally occurring glutamates. Flavor-enhancing glutamates are naturally present in roasted nut pastes, cheese and cheese oils, shitake and porcini mushrooms, and whole tomatoes. Their flavor profiles allow formulators to take down the sugar level.

Jenn Farrell, Director of R&D at CBCI, provided examples of sugar reduction in baked goods. In bakery applications, the most straightforward path is to use different types of syrups, fruit pastes, purees and fiber powders. Date paste worked well in a brownie; it binds moisture, extends shelflife and doesn’t count toward added sugar. Enzymes like maltase or glucoamylase will break down their respective substrates to glucose. She also suggested that dextrose, which has half the relative sweetness of sugar, binds water and aids in moisture retention.

Farrell noted one negative: replacing sugar with a combination of many ingredients conflicts with a clean label objective.

Click on the phrases below to see related articles on these topics at FoodTrendsNTech.com.